West System Mixing Ratio

West system mixing ratio. Gflex epoxy is resilient enough to bond dissimilar materials and flexible enough to absorb the stress of expansion contraction shock and vibration. The pumps are designed so that a. Mixing Ratio by Volume.

Short tutorial on proper dispensing and mixing of WEST SYSTEM Epoxy. Watch this short tutorial on dispensing and mixing WEST SYSTEM epoxy safely and with minimal waste. The resulting cured epoxy is a rigid high-strength moisture-resistant solid.

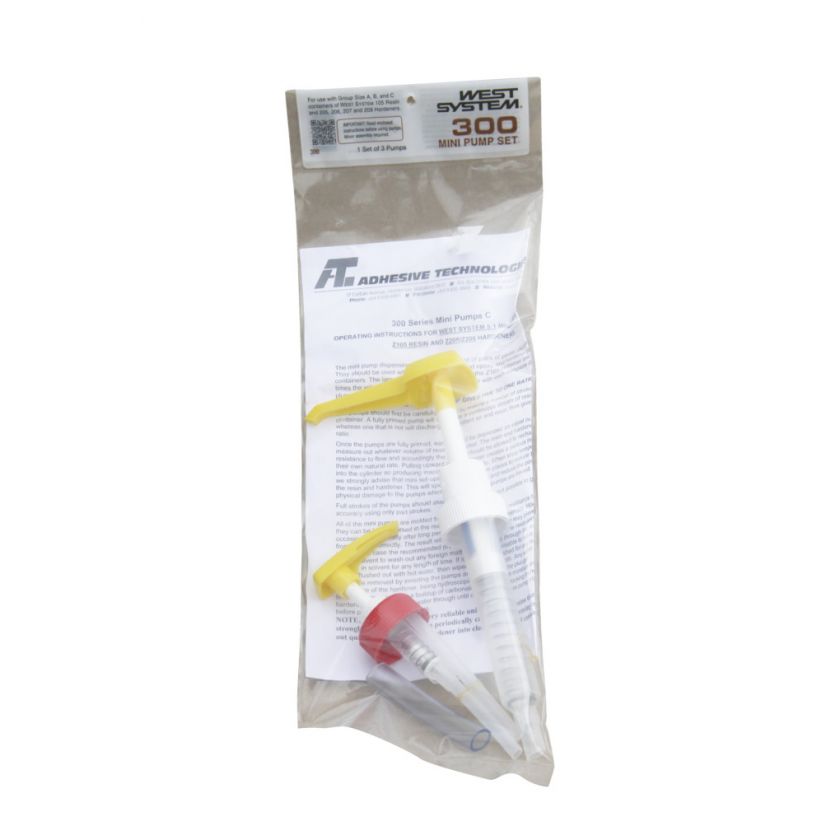

WEST System dispensing pumps provide a convenient clean and accurate way to mix epoxy resin and hardeners in the correct ratio. The mixing pumps can also be a great time-saver if you are going to be mixing epoxy often. 1 to 619 1 Mix viscosity at 72F ASTM D-2393 725 cps Pot life 100g at 72F 20 to 25 minutes.

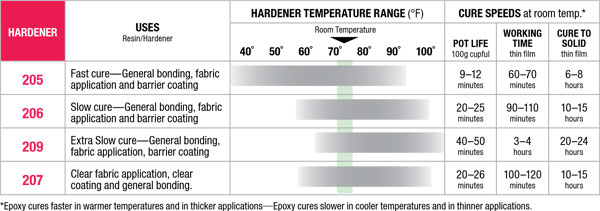

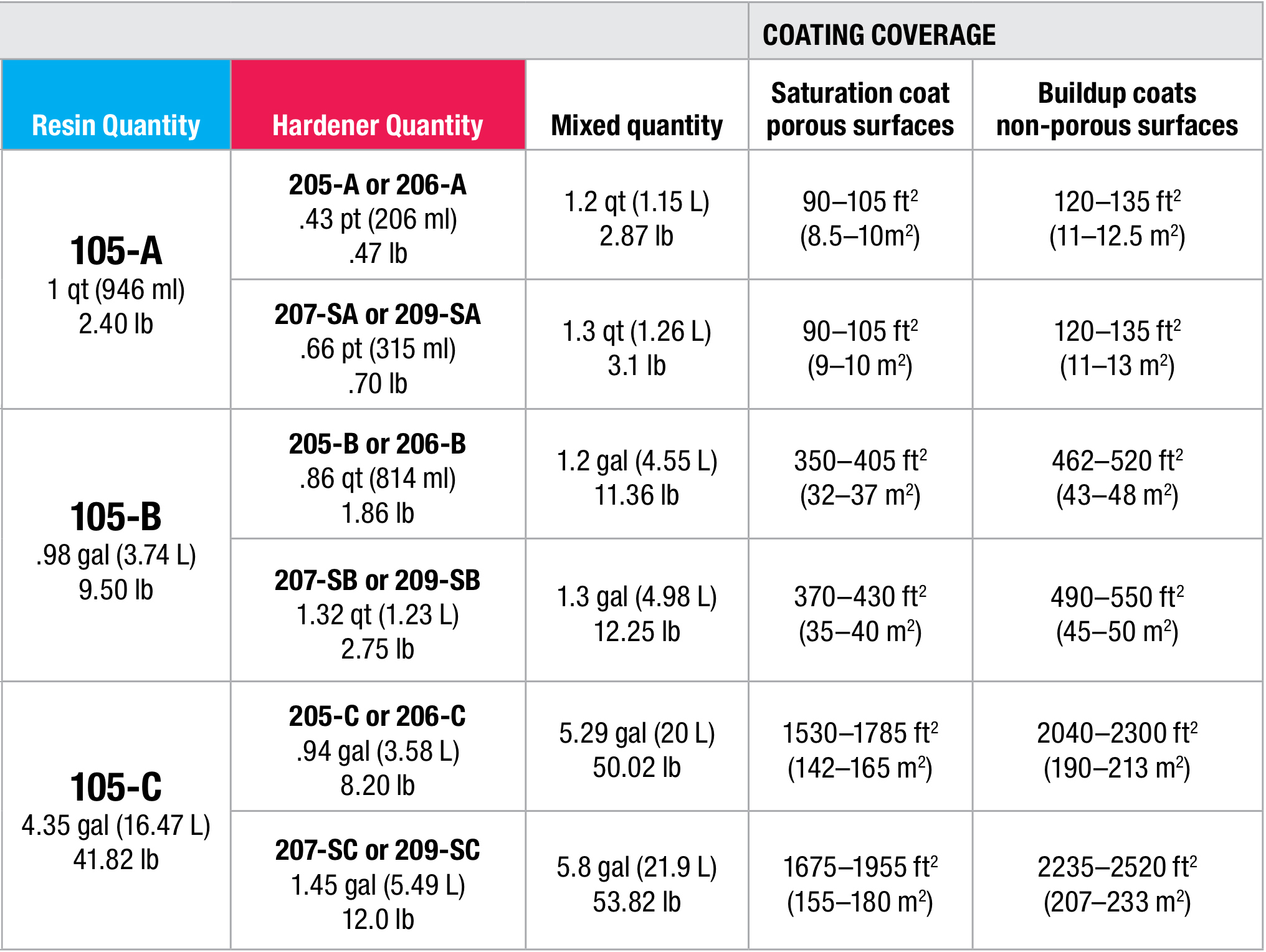

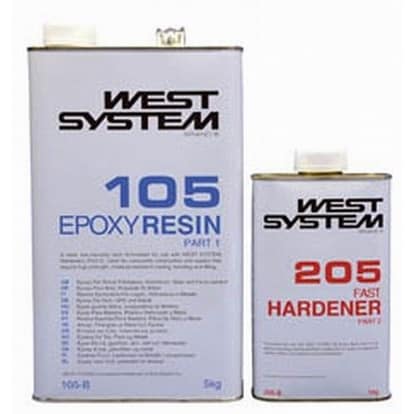

Mix it with WEST SYSTEM 105 Resin in a five-part resin to one-part hardener ratio. 207 and 209 Hardeners are mixed with 105 Epoxy Resin in a ratio of 31. Another method for metering by volume in a straight-sided container is to mark a paint stick at 5 parts 105 Resin and 1 part 205 Fast or 206 Slow Hardener.

Ad Sell your used HDD mud mixers fast - list for free. To make sure you get the proportions right we highly recommend purchase of the 300 Mini-Pump Kit which meters the hardener and resin in the exact proportions you need. Each pump kit consists of two pumps - one for the epoxy resin and one for the hardener.

At the proper mix ratio the number of chemically reactive sites in the resin balances the number of reactive sites in the hardener. For group sizes A B and C 205 and 206 Hardeners are mixed with 105 Epoxy Resin in a ratio of 51. Reusable 5 12 mixing stick for West System Epoxys and Resins.

West Systems entire line of epoxy products are explained in this West Marine buyers guide. As packaged the pumps are ready to install on Group Size B containers.

At the proper mix ratio the number of chemically reactive sites in the resin balances the number of reactive sites in the hardener.

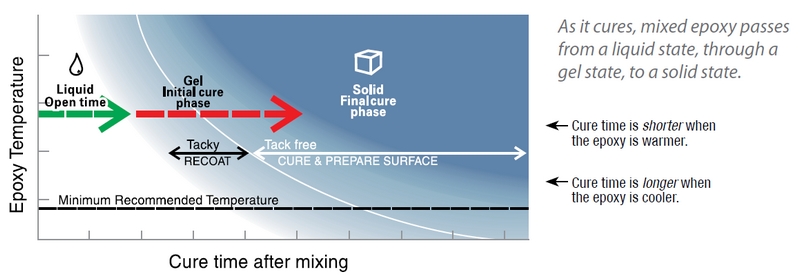

Mix it with WEST SYSTEM 105 Resin in a five-part resin to one-part hardener ratio. 1 to 619 1 Mix viscosity at 72F ASTM D-2393 725 cps Pot life 100g at 72F 20 to 25 minutes. West Systems entire line of epoxy products are explained in this West Marine buyers guide. Gflex epoxy is resilient enough to bond dissimilar materials and flexible enough to absorb the stress of expansion contraction shock and vibration. Choose the hardener that gives you adequate working time for the job youre doing at the temperature and conditions you are working under. A package of extension tubes for the smaller Group Size. Calibrated to deliver the proper working ratio the West 300 Mini Pump Set includes one resin pump and two hardener pumps. For example put a mark at 125 for the resin then another 025 above that put a mark for the hardener for a total of 15. The combination of 105 Resin205 Fast Hardener has excellent bonding and coating properties.

3 to 1 MEDIUM Epoxy Hardener. The mixing pumps can also be a great time-saver if you are going to be mixing epoxy often. Dispensing and Mixing WEST SYSTEM Epoxy. The resulting cured epoxy is a rigid high-strength moisture-resistant solid. Small batch Mixing for West Systems Epoxy. For example put a mark at 125 for the resin then another 025 above that put a mark for the hardener for a total of 15. A package of extension tubes for the smaller Group Size.

_Page_2.jpg)

Post a Comment for "West System Mixing Ratio"